Custom Water Cooling System - Questions and Answers

Q&A: here I have collected all the newbie questions that arose during the first assembly of the custom CBO! Hope it helps someone!

What is better: to make one common circuit with a video card and a processor, or two separate ones?

In terms of the effect of temperatures on the coolant, it is best to have one common circuit. Since under any load conditions, after half an hour or an hour, the temperature at the outlet from the heat-generating electronics and at the outlet after the radiators is no more than half a degree. Two different circuits are used in several cases where the flow capacity is not sufficient and the flow resistance in the system is high.

To unload one circuit, several closed systems are made. But it is recommended to use a circuit with two pumps in one system, since in a real load at maximum all devices rarely work, the load is variable. And the device that is hotter at this moment will receive better heat dissipation, because in the aggregate more radiators work on it.

Several separate circuits are also used when consumers have different heating stability. As an example: a video card can work stably up to 60 degrees on the chip, a processor - up to 90 with strong overclocking. Which, in turn, can raise the temperature of the liquid to 45-50 degrees (with a weak WTO) and up to 40 (with a normally designed WTO).

In the same common circuit, you can put an SSD or optane with high temperatures for stable operation of about 90 degrees on the chips. And components such as RAM, HDD, are very sensitive to temperature. As an example, DDR4 3733 MHz CL 14-14-14-28 memory, at 1.48 they already lose stability at 51 degrees. Given that the water temperature reaches 45 degrees and by itself can warm up the memory, which also generates heat, it is worth considering these points when extreme overclocking the RAM. It is desirable to organize a separate cooling for this - air or water.

Which tubes are better - rigid or flexible?

A lot depends on your ambitions. For those who do not want to "steam" and want to spend enough on a budget, we can recommend flexible ones. Best viewed with PrimoChill coating. They have a longer service life than conventional ones, and do not become cloudy longer.

If you want beautiful and richer, then among solid tubes there is a greater choice. There are plastic Acrylic or PETG, they differ slightly in the nuances of molding, an ordinary building hair dryer and accessories are used. But they are also not durable, the liquid in such tubes “wears out” faster, can become cloudy, and when dismantled, they are brittle.

Next comes luxury materials. Firstly, these are brass tubes that can be painted and a rather expensive tool is used to form them (their walls are thin, which can look harmonious in compact assemblies without losing the efficiency of the coolant flow). And secondly, tubes made of borosilicate glass, for the formation of which a gas burner is used. The last two should be chosen when you strive for the ideal and are ready to spend money on it. Since there are very few glass forming specialists left, it is easier to buy a blank with one elbow and connect two elbows from two parts than to mold two or three elbows from one blank. Borosilicate glass and brass withstand very strong pressure drops, while glass is still completely inert.

What is the best tube diameter?

If you take into account a technical point of view and think about efficiency, then it is better to look at a larger internal diameter. This will create fewer flow obstructions in the system. In the case of flexible tubing, the thicker walls will prevent the hose from creating a kink and obstructing or stopping the flow in the system. Well, you need to think about the length and how to lay this hose in order to avoid unpleasant kinks. The consequences can range from a stoppage of flow and non-functioning cooling, to a breakthrough at a weak point, most often at the point where the hose attaches to the fitting.

In terms of aesthetics, sometimes thinner tubes look more harmonious.

From what material to look at the water blocks of the video card and processor: copper, nickel-plated copper, silver?

In my opinion, the best option is copper. It is cheaper and more efficient than nickel-plated copper.

Silver is better at dissipating heat than copper (because of better thermal conductivity) when the system is properly tuned by 10%, but the price is 2-3 times higher. Also, dissolved silver ions have biocidal properties, while silver is inert enough not to pollute the system in the presence of copper radiators.

In nickel-plated copper, I do not see the point at all. It was created so that when different metals (like copper and aluminum) are in the system, galvanic processes in the form of oxidation and rust do not occur. In simple terms, it is justified to use it with aluminum radiators. You only need to buy such a water block from a good manufacturer, and not from Ali Express, otherwise such a coating will quickly peel off and ruin the entire system. Moreover, the difference in price with a similar water block made of copper or nickel-plated copper can be up to 30%

Which radiator is better - copper or aluminum?

The difference in price between them is from 10 to 20%. Aluminum is used most often in disposable, maintenance-free AIO systems that are discarded after a year or two. Therefore, the manufacturer strives to save on absolutely everything that is possible or impossible, and in terms of effectiveness it is similar to supercoolers, which are also cheaper.

Having paid a little extra for copper radiators, you can cheaper buy a more efficient copper water block for both the video card and the processor. Therefore, in the end, the money will turn out to be +/- the same, and the efficiency is higher. And at the same time there will be no problems with galvanic reactions, less often you will have to change the liquid.

If you take a thicker radiator, will it be cool and cold?

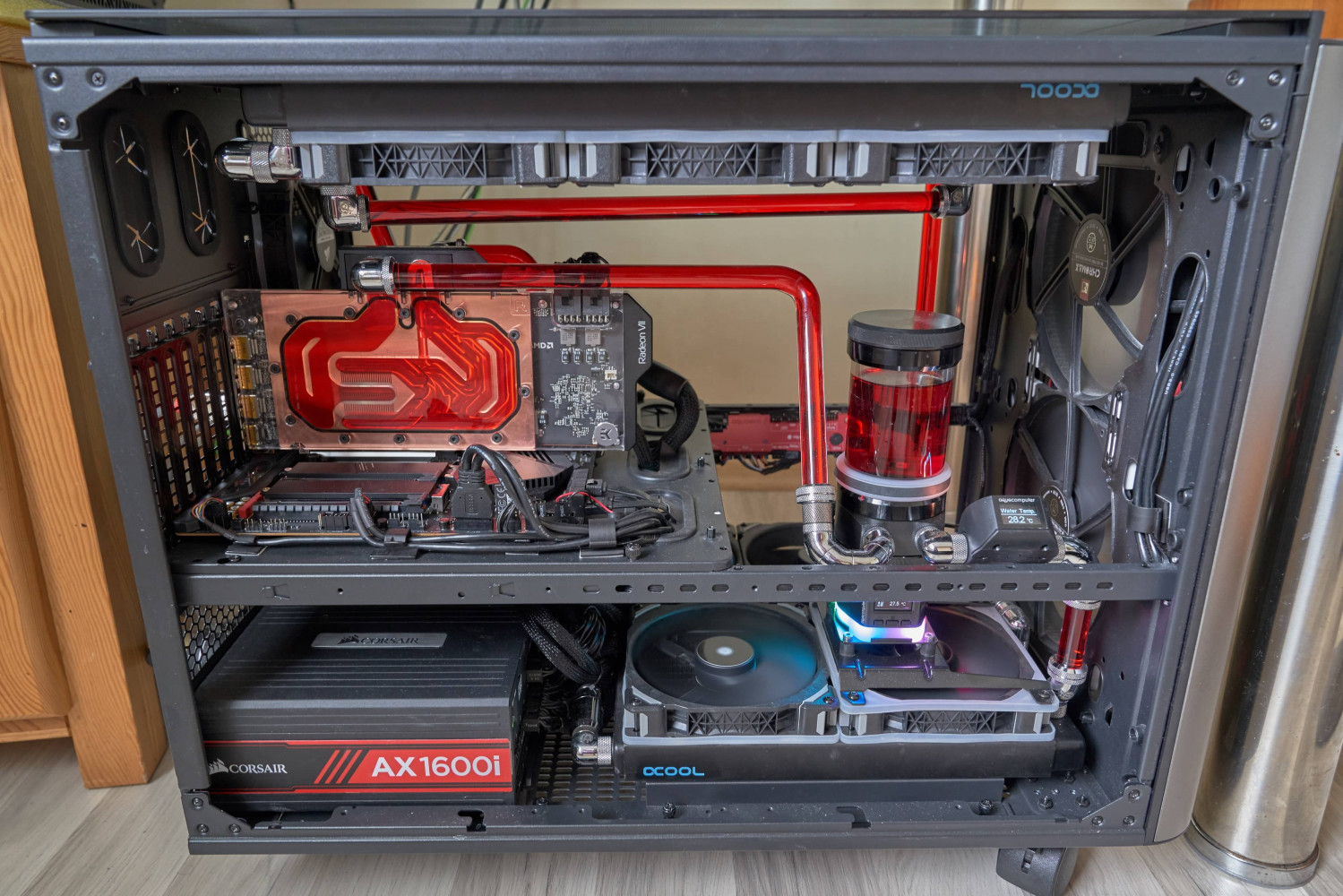

Yes, if a few conditions are met. Firstly, radiators from 45 mm have almost perfect flow resistance, which means that on the same pump you will get more performance, but you will need much more coolant (which is sometimes quite expensive). In order for this radiator to be effective, a strong airflow must be provided through it. As a result, higher fan speeds are needed. If the thickness is more than 45 mm (50 mm and above), then the fans are needed from two sides: on the one hand for blowing in, on the other for blowing out. Then you can fully realize the potential of thicker radiators.

What else interesting you need to know about radiators?

Now they are trying to think over radiators better and optimize them for different air flows. For example, there are thin lamellas, they are well suited for low-speed fans, for people who prefer silence. Thicker radiators require more airflow.

Based on experience and tests, we can judge that in most cases the thinner the radiator, the better it removes heat, but cuts the water flow rate more. The thicker the radiator, the more efficient the fans, which must spin at high speeds.

In my system, the flow rate is 155 liters per hour, which is enough to pump 4 radiators with a thickness of 30 mm (11 sections). At the same time, water blocks work as efficiently as possible. As a conclusion, there is no point in a radiator thicker than 45 mm.

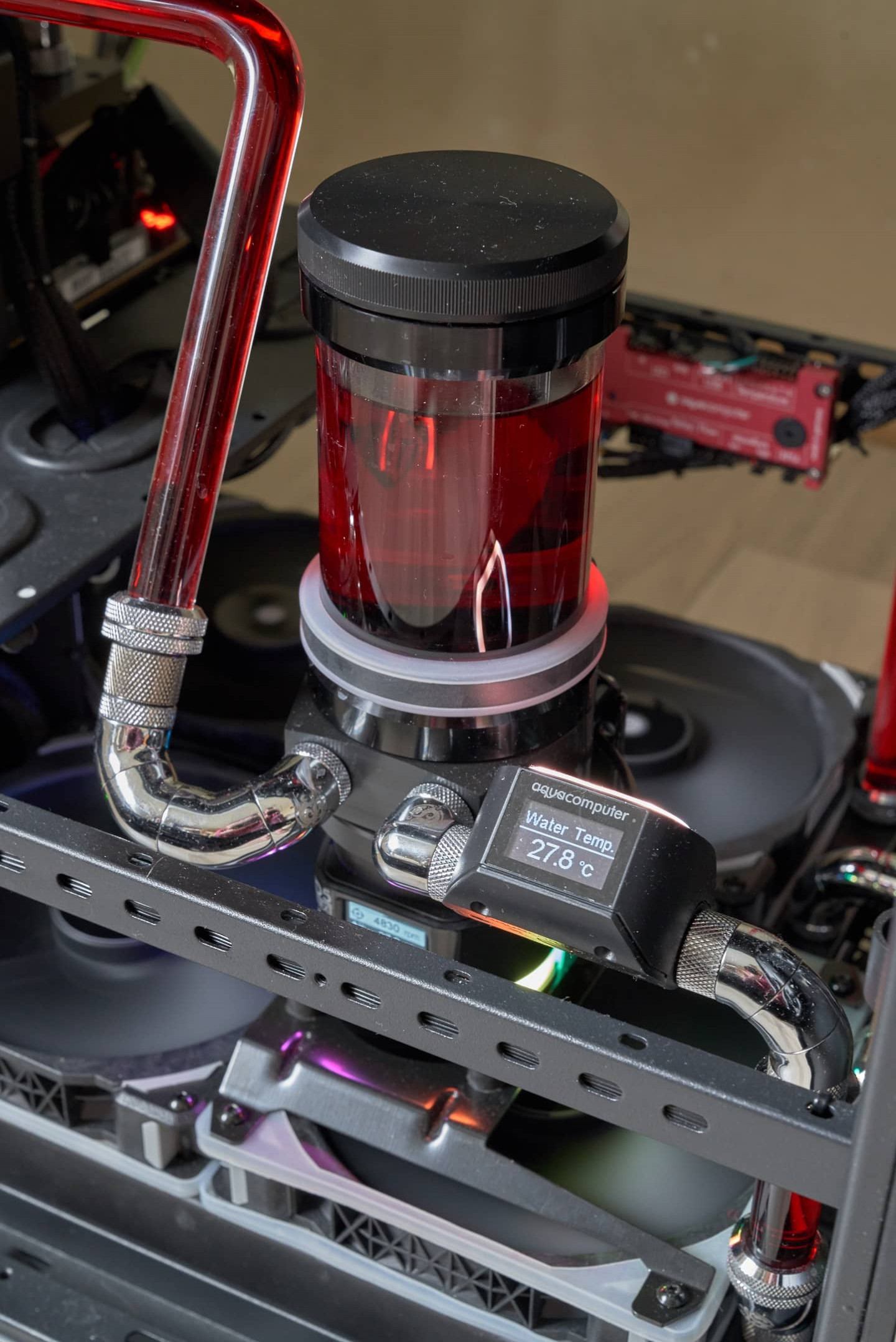

Which coolant is better to take - pastel or transparent, or maybe dielectric?

If you are a beginner, and there is no device to check whether the system holds pressure, and there is doubt inside, then it is better to buy a dielectric one. Of the benefits - in the event of a breakthrough, nothing will burn. Of the minuses - the liquid is only transparent and colorless. It is also subject to wear and after six months loses its dielectric properties. But in principle, if there was no breakthrough at the launch stage or within a month, then it fulfilled its function and the system is reliable.

What about pastels? The composition of such a liquid contains suspended solid particles, as well as anti-caking agents - so that sediment does not fall out and a homogeneous mass is kept. In any case, the liquid wears out, and it is not uncommon for these particles to precipitate. Therefore, the wear of such fluids is higher, and they need to be changed more often. On the plus side, they look stunning and very beautiful! Of the pastels, the Mayhems brand concentrate is considered the most problem-free . And if you consider that among liquids, especially popular brands, there are many fakes, then it is better to take them directly from the manufacturer's website, even if it will be 2 times more expensive in the end. Or do not forget to take along with other components when ordering in these stores.

If you want a less "capricious" fluid, then you can buy a clear coolant.

Can I use fans from my old computer?

It can be used, but in the vast majority of cases they have low air pressure, and they are optimized in such a way that they have the maximum declared air pressure efficiency when mounting fans at a distance of 20 mm from the radiator. This is the most important parameter for flushing the radiator.

If you attach fans close to the radiator, then its efficiency will drop significantly in relation to the nameplate values. Therefore, having studied the characteristics of your fan, you can think about one adapted to the CBO.

Corsair ML 140 PRO is considered a worthy option. It is one of the few that gives good performance at different fan speeds. While the vast majority of other models of fans at low speeds are practically useless and give out the declared characteristics only at the maximum value of the fan.

Therefore, it is very important to watch the tests on the entire fan speed range! Since they are usually left to work at 600-1000 rpm! And at maximum speed they are set to blow through the radiators, as is the case in modern laptops. There is a program that programs this function to briefly turn on the fan at system startup in order to knock fine dust off the radiator.

Do I need to buy a fan control board separately?

If you are planning a budget CBO assembly, then you can easily get by with the motherboard. Just look at the maximum current load that can be applied to the motherboard.

If the motherboard is designed very well, then the fans have minimal impact.

If you are building a system with a large number of fans, and also planning extreme overclocking, then my answer is definitely yes! A separately well-designed board will allow you to connect many more fans, unlike a motherboard.

Also, there are electric motors in the fans, which provoke interference in the system, especially during start-up (as they create the effect of starting current in the system). When connected directly to the motherboard, these interferences go to it, and then to other components, RAM is most susceptible to this effect. If the fans are placed on a separate control board, then the interference passes through the power supply, which dampens it much better than the motherboard can do. So, if you have the funds, then this fee will definitely not be superfluous. Plus, usually this comes with high-quality screw software for controlling fan speed.

If two radiators can be installed in the case for 120 mm 4 sections or 140 mm 3 sections. What to choose?

Here you can calculate the effective scattering area. In the first case 120x480=57600, in the second 140x420=58800. As you can see, the variant with a 140mm radiator is more efficient and cheaper. Since a 3 section radiator will be cheaper and you will need 2 less fans! Therefore, we are definitely looking for cases with the ability to install 140 mm fan radiators!

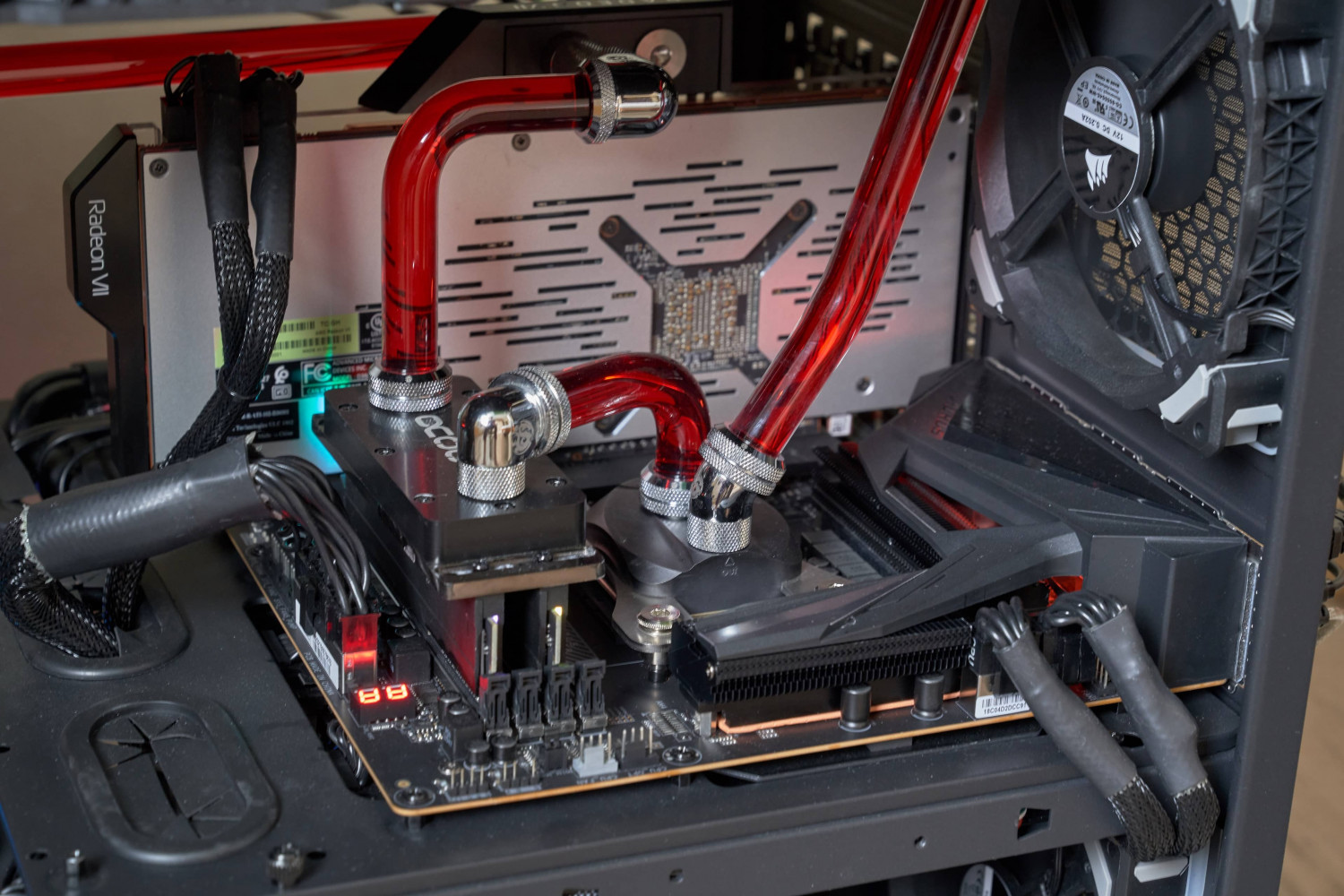

What do you need to overclock the video card permanently into the trash?

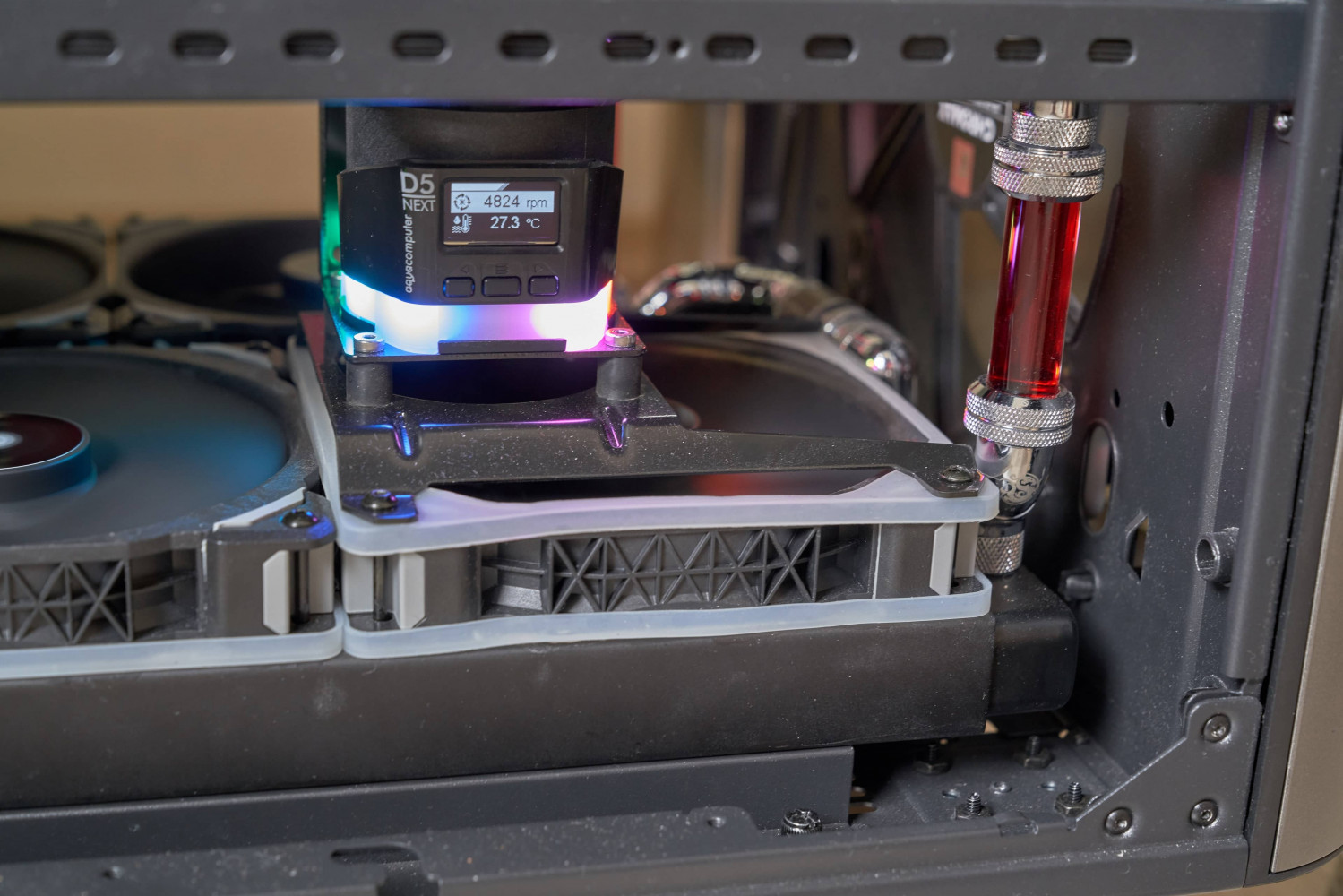

Depends on the level of heat dissipation of the graphics chip, as well as video memory. As practice has shown, if the total consumption of a video card during overclocking does not exceed 350 W, then a flow rate of 150 liters per hour is sufficient, which can be provided by any D5 pump with a maximum capacity of 180 liters. (In my system, it produces 155 liters per hour at maximum power.) It is desirable to look at water blocks that are more modern and proven. A performance of more than 150 liters no longer makes a noticeable difference. The radiator is enough for 3-4 sections of 140 mm for a video card. If the consumption of a video card during overclocking goes beyond 450 W, which the current owners of Nvidia 3080 and 3090 cards faced, then it is much more difficult to remove such heat, and the flow rate should be at least 260 liters per hour, which can already be provided by 2 pumps connected in series.

It is also worth looking at a more efficient thermal interface. One of the best is Thermalright odyssey, thermal pads and thermal paste. With thermal paste there are nuances when applying, so it is not recommended for beginners.

You can also pay attention to the thermal grizzly kryonaut. But they are more often found fake and give worse results than the ubiquitous MX-4. And despite their excellent performance, they do not always give a tangible gain compared to the same MX4 (sometimes within the margin of error), and the price is much higher. And in some cases, the gain reaches 12 degrees when replacing the standard thermal interface.

Here, at last, we have thought over what we want. Read the reviews and find out the approximate prices. And we ask ourselves:

Where is the best place to buy water cooling components?

Everyone has their own answer. If you wish, you can buy from the manufacturer, since they have a web page with an online store. But the largest of them is the German retailer https://www.aquatuning.de/ . All suppliers who work with him try to fill their store in the first place, and then their own, prices are slightly higher. But if you take everything from them, and not from different sites, you will save on shipping, which in the end can be cheaper!

Next, we go directly to the manufacturers: there is https://aquacomputer.de/ . It is best to buy control boards from them, a unique pump D5 Next with electronic control. Program updates after two years of use are paid, but no one did better, in my opinion.

The best fittings (their chrome is considered eternal and will never come off) are https://shop.bitspower.com/ . You can also agree in this store that the invoice is invested with a smaller amount, and the payment is divided into 2 parts: one - to show the customs officers, the other surcharge after the fact. This way you can save on VAT.

Also now there are shops where it is possible to pay with bitcoin. In this case, the law will not allow you to take VAT and duty from you when the parcel enters the country (in the EU - for sure, according to the laws of your country - check).

https://www.ekwb.com/shop/ - a confident middle peasant, where you can assemble a complete set without unnecessary troubles.

https://shop.watercool.de/ is another good top cooling manufacturer.

In these stores, you can definitely not be afraid of fakes and the service is at a high level.

Links will be updated based on your suggestions.

Finally, we waited for the moment when everything we needed arrived!

What surprises might you encounter?

I picked up a radiator - there is some sand inside, what should I do?

The vast majority of radiators are manufactured by welding. Because of what, different fragments remain inside the radiator. For reasons of economy in production, no one thoroughly rinses them. The maximum that is possible is quality control by pressure. Therefore, be sure and very thoroughly flush the radiators before installation. After the inside is dry and the use is not planned soon, isolate the inside of the radiator from dust.

Plastic hard tubes break or do not want to enter the fittings, what should I do?

Cutting the tubing to size and attempting to fit it into the fittings can result in breakage as they do not fit into the grooves very well. Therefore, at first it is better to make chamfers both outside, for better installation, and inside, so that plastic hairs do not get into the system.

If after this the tubes do not go into the fittings, you need to make sure that the outer diameter of the tubes matches the inner diameter of the fittings. If everything is chosen correctly, but it comes in very tight with a high risk of breakage, then you can use grease. I use a Q-tip that has been sprayed with a little WD-40 and apply a thin, barely visible layer to the end of the tube and to the rubber seal in the fitting. WD-40 has been designed to be non-degrading to rubber and plastic parts (be careful, you need to be aware of which WD-40 plastic materials are best not to use), have cleansing properties, and also have light lubricating properties. If a lot of lubricant has been applied, then the excess must be removed so that they do not float in the system.

Solid tubes in fittings dangle dangerously

All manufacturers have different clearance tolerances, the cheaper the fittings, the more likely it is that these clearances are not met. Heard frequent complaints about EC fittings. But I have not seen circuit breaks from personal experience, although they talk about it. But these fittings also have the advantage of being more able to angle the tubing at the attachment point to get into the next fitting with a lower quality tubing. Therefore, if you have chosen the correct diameters of tubes and fittings, there should be no problems.

When is it better to lay the cables - before or after assembling the CBO?

The main design and installation work is best done after you have installed all the components, but before you mount the pipes and start the system. After the complete installation of the system, it will be possible to make only small touches, otherwise you will curse everything in the world. Further, if, in your opinion, something is missing in the case for cable management, then you can use accessories. It can be a thermoplastic braid: several cables are connected together and singed with a lighter. Then it will shrink to the diameter of the wires and will look like one whole. Hooks on double-sided tape will also help so that the wires on the walls of the case sit and do not hang out. Well, and a lot more. I watch them here https://www.aquatuning.de/modding/ . Links will be updated based on your suggestions.

What is the best way to organize the ventilation system in the case?

First of all, it depends on which case you have chosen and what opportunities it gives.

Secondly, the fans should always blow onto the heatsink in case of one-sided mounting. Or on the one hand - for blowing, and on the other - for blowing out when mounted on a radiator on both sides.

Fans in relation to the case - for blowing in or for blowing out of the case?

Fans, which are located on the top wall of the case, are always blown into the external environment.

If fans without heatsinks are mounted on the rear wall of the case and there are no devices with their own fan in the system , for example, an air-cooled processor or a video card with similar cooling, then it is better to direct them to take air from the external environment.

If the system has, say, an air-cooled video card, then the fan on the back wall is definitely blown out, since the video card generates a lot of heat that needs to be removed outside the case.

Fans on the bottom of the case . Here you need to look at the situation. If without a radiator, then definitely on the air intake from the outside to the inside. If with a radiator, then you need to look at whether the case will be open or closed. In the case of an open case, the fans blow air out of the case, in the case of a closed case, you need to understand whether the air intake into the case is well organized, and, based on this, make your decision.

front wall.Ideally, there should be no radiators on the front wall, since fans that take air from outside are needed to cool minor components on the motherboard, hard drives, SSDs and RAM (direct fans can also be installed on RAM). If your case is quite compact and it is not possible to organize air intake into the case by other means (if the case is closed), then in the front part the fans blow into the case. It is also worth considering that the heating or cooling of the BPM zone of the motherboard is highly dependent on this factor, which also affects the stability of the system. If the temperature of your BPM zone in the stress load does not exceed 55 degrees, then the front fans can be made to blow. If the temperatures are higher, then only for blowing, regardless of whetherAs an example: at a liquid temperature of 45-50 degrees, and a BPM zone of 55 degrees, most likely the air will additionally heat up this BPM. If the water temperature is 40 degrees, and the BPM is 70-90, as it happens in the vast majority of cases, then the warm air from the front radiator will cool the BPM zone (in systems with air-cooled BPM zone). Similar solutions apply to RAM sticks as well.

If desired, you can always calculate the theoretical volume of air that enters the case and exits the case outside of it, using the technical characteristics of the fans. But in practice, one can only try to get closer to this, since often poorly designed cases for the sake of beauty become an obstacle to obtaining real factory results.

It is also worth considering the airflow resistance of radiators, radiator mounts, filters and of course the dust that will accumulate on the filter, radiators and fan blades over time. Therefore, a reasonable decision would be to conduct experiments and see the real results of the cooling system.

I also want to add that fans do not always run at full speed, and their efficiency does not change linearly with rotational speed. Further: a fairly common occurrence when, when the fans are started at full speed, the air blows in the opposite direction, as it encounters an obstacle and unnecessary turbulence occurs! If you want to exclude this, then you will have to modify the fasteners of the radiator housing exactly to your dimensions. Since the mounts and cases are made primarily for the sake of versatility, not efficiency, not to mention the frills of appearance, for the sake of which absolutely unacceptable things are sacrificed! Here I want to say that the walls of the buildings are made with poor ventilation(to be more precise, they are tightly closed!), and when these walls are installed, the temperature of the system rises by an unacceptable 10 degrees in almost all cases! dust filter, which will definitely need to be finalized! ..)

Important note: Ideally, there should be at least 20 mm of free space in front of the air intake fans, then the fan will create the air flow required for the radiator with maximum efficiency.

And then the moment came when we collected our baby. We rechecked everything 10 times, but as it turned out, this is not the end...

How to fill in coolant so as not to damage the pump?

According to the specification, dry operation of the pump is strictly prohibited . Therefore, the question arises: how can liquid be poured into the system so as not to damage the pump, including computer components, by hard shutdown? To do this, we will need to disconnect the 24-pin power wire of the motherboard. And put a jumper on this wire 24 Pin Power Supply Jump Start Connector. It usually comes bundled with more expensive motherboards. But if it so happened that this is not included in the kit, then it can be bought separately.

As soon as we de-energized the motherboard by pulling out the wire and putting this jumper on it, we have the opportunity to turn off and turn on the connected peripherals with the on / off toggle switch. on the power supply.

Fill the reservoir with liquid, turn on the power supply, you will immediately see that the pump has started working and started to distill the liquid. As soon as the liquid has approached the bottom, immediately press the toggle switch off. Add liquid to the reservoir and repeat the procedure until the system is completely filled. Only after the circuit is filled and you have not found leaks anywhere, you can connect the 24-pin wire to the motherboard. When doing this procedure, it is advisable to put paper moisture-absorbing napkins on the electronic components, so it will be easier to see where it drips and will not burn expensive components unnoticed.

I filled the reservoir with coolant, turned on the pump, but the liquid is not pumped. What could be wrong?

First of all, you need to check if the pump is working? Put your hand on it: with a properly working pump, there should be vibration. If there is vibration, remember how it was assembled, is everything assembled correctly? If you do not remember, you can try to disassemble the tank with the pump and see what might interfere. If everything is assembled correctly or you reassembled correctly, but the liquid is still not pumped into the circuit, then the following question arises.

What the hell!? — "Siphon effect"

The point is that if the reservoir is small and below the top radiator where the water is supposed to go, then there is not enough water column pressure to pressurize the air in the system, even with the pump running. In this case, the following solutions help:

At the highest point of the circuit, you need to unscrew the hose or plug on the radiator to remove the increased air pressure. Since when filling the tank there are two ends (the inlet and outlet of the liquid are in the water), air is trapped in the system, which is difficult for the liquid to push through. In 90% of cases this is enough. If this does not help, then you need to create additional pressure on the liquid in the tank or on the air by vacuum.

To put it simply, you need to change to a higher tank or, in the place where we unscrewed the plug, suck out the air. As soon as the water reaches the top position and begins to pull water along the bottom of the system, the pump will pump the liquid without difficulty. Naturally, all plugs must be closed as soon as we see that the pump is coping so that nothing spills out of them (or return the hose that was unscrewed to its place). It is also useful to unscrew the plugs at the top of the system, in problem areas, to bleed air in air pockets!

We filled the system with coolant, checked that it was not leaking anywhere. We connected the motherboard to the power supply, presses start and ...

What again?! Why doesn't it start? — "Cable"

This means that the power supply goes into protection due to incorrectly connected cables. If you didn’t save on the power supply, it will turn on the protection system, and if you save, the incorrectly connected device will burn out or, at best, the cable will light up, and you will feel the charm of the smell of burnt wiring. If you want to buy beautiful custom cables, then before buying, you need to check whether they are suitable for your power supply, as manufacturers often make different pinouts. I ran into this while trying to use cables from Seasonic for a Corsair PSU. As it turned out, they have different pinouts and are not compatible! Therefore, if you do not have the opportunity to find out what pinout is used on custom cables, then it is better to purchase extension cords for standard ones! You should also check the connections of other cables, which may be set incorrectly. For example, USB 2.0.

Do I need to flush the system with distilled water before using a special coolant?

Despite the fact that we washed everything separately, there is still a need for additional washing. Fill with distilled water and run it through the system for a couple of days. Drain, pour distilled water a second time and drive for at least a day. Drain and fill after that already a special coolant.

I have an acrylic waterblock video card. I see a deposit of an incomprehensible color on the cooling fins of the chip, what could it be?

In the vast majority of cases, this is ordinary dust that remains in the radiators. Since the assembly of the system and its first start-up takes a long time, and the holes were not closed or sufficiently insulated, this dust gets inside. Therefore, it will be necessary to drain the water, dismantle the video card and the processor water block (usually it accumulates on the ribs of the VK water block and acts as a kind of filter, and the CPU most often does not get to the water block, but it is better to double-check), disassemble and clean, as this will affect the thermal conductivity and speed flow. We collect and refill with distilled water to clean the system.

Can I keep distilled water as coolant and save on buying special coolant?

Absolutely not! Distilled water is considered a strong solvent, if you do not change it to a special liquid intended for cooling within 2 weeks, galvanic reactions will begin in the system! And it's good if you can fix it, if not, then many components of the system will need to be replaced!

What else would you like to do?

If the tank does not have a pressure relief valve, then it is better to leave it open for the first week. This is necessary so that bubbles that have stuck to the walls come out of the system (usually we can observe them on the walls of the tank or acrylic surfaces), and also squeeze out air bags that interfere with cooling. Give the system a good shake a few times a day so that the accumulated bubbles break off the surface and exit the reservoir freely. If you are afraid that the coolant will splash out during shaking, then you must first close the tank, then open it to release excess air pressure.

After that, we close the system and rejoice for at least a year until it is time to service it. My congratulations, you did it!

As you use CBO, the following unhealthy problems may come out:

I have a precipitate: why, what to do?

If you have used a pastel coolant and have not changed it for more than a year, then the components in this fluid have worn out, this fluid must be urgently changed and the system cleaned.

It can also be the reason for a long non-use of the computer, when the suspended particles simply settled. Another reason for the precipitation of a new pastel coolant may be non-compliance with technological standards in production, even if it is the original. In this case, it is quite possible that you bought a fake.

If this happened with a clear liquid, subject to use for more than a year, then it also urgently needs to be replaced. If precipitation fell in a clear liquid during the first month of use, then you have a counterfeit. It needs to be urgently drained, purged the system and filled with the original.

There is foam in the system, is this normal?

Foam is definitely not normal. The coolant contains antifoam agents. If this happens after a year, then the fluid must be urgently replaced, as it has exhausted its resource. If this happens after a month or six months, then you have a fake or defective liquid, which was released in violation of technological processes in production.

So, you have been enjoying high performance and extreme overclocking for a long time. Everything was fine, but inevitably there comes a time when you need to service the system or modify the computer.

When is the best time to change the coolant?

Usually, the manufacturer writes on the packaging how much it is guaranteed that its liquid can be used without harming the system. But in reality, several factors affect the lifespan of this fluid:

Operating temperature: The higher the operating temperature, the lower the service life. Typically, a guaranteed service life implies that it does not exceed 40 degrees. If the operating temperature is higher, the service life will be reduced.

The presence of different metals in the system: the composition of the coolant contains components that prevent the formation of various chemical reactions. If there are any, they also shorten the life of the coolant.

When there is already rust or stains: when there are already lesions in the system, then, naturally, the additives in the fluid have to neutralize all this intensively, which also reduces its service life.

When the system is contaminated: in fact, the coolant already contains components that block the growth of bacteria and fungi. But if, for some reason, you brought them there or washed them poorly when it was time to service the system, then these microorganisms remain in the system. As a result, inhibitors work worse and wear out faster. Since they are aimed at suppressing reproduction, and not its elimination.

Are there any devices that measure the quality of the coolant?

At the moment, I know of only one device that measures the electrical conductivity of a liquid and, based on these results, outputs data on the quality of the coolant. If the electrical conductivity of the liquid increases, then the additives in the liquid already work worse. This means that a lot of things have already dissolved in the liquid and the necessary chemical reactions for neutralization have taken place. The device is called Aqua Computer high flow NEXT. It does not show the results very accurately, but in principle this is enough to know what condition the coolant is in. It also shows the flow rate or pump performance with temperature.

But you can do without it by writing with a black marker on the black surface of the tank so that you can see the date of replacement of this fluid at a certain angle, based on the manufacturer's recommendations.

How to properly drain the coolant?

The tap from which the liquid will drain should preferably be located at the lowest point. This must be taken into account when designing your system. We pull or wind the hose onto the faucet and the lower end should be below the level of your computer. At the highest point, unscrew the air intake plug. Then you will merge the liquid in the maximum possible amount. And then, according to the situation, tilt the body in the right directions and drain the remnants.

How to properly remove hard tubes?

For these purposes, it is desirable to have gloves with a tenacious surface, then the effort to remove the tubes will need to be applied less, which in turn reduces their damage. Well, you won’t cut your fingers when unscrewing the fittings, since the edges can be sharp. Shoot carefully, in a circular and swaying motion. It is better to place paper absorbent wipes on all electronic components and have a small basin nearby in order to be able to quickly substitute. With flexible ones, everything is much simpler: unscrew it, remove it.

Can dust on electronic components be vacuumed?

This categorically does not need to be done, despite the fact that many people neglect this advice and nothing happens. It is best to use compressed air cylinders to remove dust.

What else needs to be done to make the system last longer?

It is advisable to remove all water blocks and disassemble. When you disassemble them, you will need to rinse and clean from the oxide film. If it is copper or silver, then lemon juice and a hard toothbrush are used, which cleans very well between the ribs of the water block. If it is nickel-plated copper, then mechanically it is better not to do anything with it, just rinse it.

Washed, collected all over again, what's next? There is a suspicion that the system is not quite clean, like it was once new. What else can be done?

Yes, this is a fairly common question, because sometimes people forget when they poured liquid, and this led to the formation of mold or a colony of bacteria in the system. If you noticed this too late and did not replace the fluid in time, then there are special additives that are added to the flush fluid (distilled water), such as bactericidal or antifungal.

Strictly follow the manufacturer's instructions for the additive.

Sometimes they cannot be combined or mixed with additives from other manufacturers! If you are lucky and the remedy helped, then you can pour ordinary distilled water to wash off the remnants of the additives. And then change to a special coolant. If unlucky, it is better to replace the affected system components.

If for some reason you are not sure that you will succeed, then it is better to trust the professionals!!!